A little known fact is that Uranium occurs naturally in phosphate rock. When phosphate rock is processed and agricultural fertilisers are made, this Uranium remains with the final product. During this process, the crushed phosphate rock is treated with sulphuric acid to extract the phosphates (becoming phosphoric acid), used to make fertiliser.

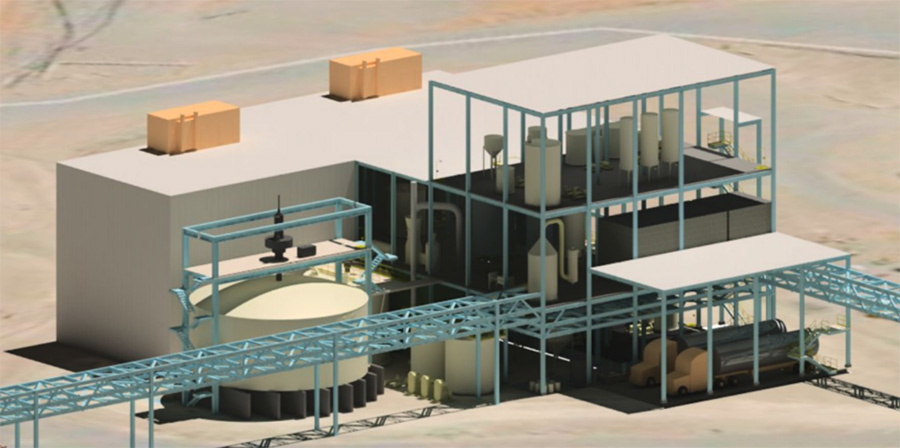

The PhosEnergy process extracts this Uranium from the Phosphoric acid prior to the final process and the end result is a U3O8-free fertiliser. The potential to commercialise this Uranium is the value add to the fertiliser manufacturing. With the recent upswing and bullish forecast for global prices, the PhosEnergy process is gaining global interest, given the potential for supply.

The PhosEnergy process has the potential to unlock U3O8 production equivalent to 15% of current global production.

To give some scale to the global market opportunity, more than 140Mt* phosphate processed annually. Approximately 20Mlb of U3O8 has the potential for extraction via the PhosEnergy process, with 6Mlb potential alone in the United States.

In addition to the US, major phosphate production occurs in Morocco, Tunisia, Saudi Arabia and China